SAR Prozess- und UmwelttechnikSAR realisiert als namhafter und unabhängiger Systemlieferant seit 1985 mit mehr als 600 Mitarbeitern an verschiedenen nationalen und internationalen Standorten Projekte in den Bereichen Kraftwerks- und Energietechnik. Das Unternehmen besitzt langjährige Erfahrung in der Automatisierung von Industriekraftwerken, sowie Anlagen zur thermischen Behandlung von Abfällen, Biomassen und Ersatzbrennstoffen.SAR bietet kundenspezifische Komplettlösungen aus einer Hand inkl. Verfahrenstechnik, unter Verwendung eigener Entwicklungen und Produkte. Spezialisten unterschiedlicher Fachrichtungen projektieren und entwickeln in projektbezogener Teamarbeit mit hohem Engagement und Eigenverantwortlichkeit. Von der Analyse bestehender Anlagen, der Konzeption des Verfahrens, über die Entwicklung neuer Lösungen bis zur Inbetriebnahme und Wartung garantiert SAR ein durchgängiges, hohes Qualitätsniveau für zukunftssichere Lösungen mit hoher Investitionssicherheit. |

ProzessleitsystemeSAR projektiert und liefert Prozessleitsysteme für Anlagen aus den Bereichen Kraftwerks- und Energietechnik:

|

Unsere Spezialisten kennen und verstehen die verschiedenen, komplexen Prozesse in der Energie- und Kraftwerkstechnik. Das gewährleistet eine professionelle Projektierung

und fehlerfreie Umsetzung. Die Inbetriebnahme kann weitgehend eigenständig erfolgen.

Unsere Fähigkeiten und unser Wissen erstrecken sich über die Gesamtheit einer Anlage. Wir bieten zusätzliche Dienstleistungen, die weit über rein technisches Know-How hinausgehen. Dazu gehören u.a. Qualitäts- und Projektmanagement, Gefahrenanalyse (SIL-Einstufung), Funktionsplanung und Unterstützung bei Behördenabnahmen. Siemens PCS7PCS7 zählt zu den am weitesten verbreiteten Prozessleitsystemen mit weltweit rund 8.000 Installationen. Das System ist im Gegensatz zu anderen Lösungen frei am Markt erhältlich. Es kann von unabhängigen, zertifizierten Systemintegratoren geliefert und projektiert werden. |

|

|||||

|

Certified PCS7 SpecialistSAR ist von Siemens zum „Certified Specialist“ für PCS7 zertifiziert. Diese Auszeichnung erhalten nur Firmen, die nicht nur hervorragende Systemkenntnisse, sondern auch nachweislich fundierte und umfassende Prozesskenntnisse in den Bereichen Verfahrens-, Energie- und Umwelttechnik besitzen. Wichtige Ziele sind eine hohe Anlagenverfügbarkeit und ein hoher Anlagenwirkungsgrad durch die optimale Ausnutzung der eingesetzten Ressourcen.SAR erhält durch die Zertifizierung direkten Zugang zu den Entwicklern von PCS7 und ist somit bei Neuentwicklungen und bei Einführung von neuen, innovativen Technologien bereits im Vorfeld bestens informiert. Dieser Informationsvorsprung wird erfolgreich in neue Anwendungen und neue Lösungen eingebracht. Siemens garantiert gemeinsam mit den zertifizierten Firmen international ein durchgängiges, hohes Qualitätsniveau bei der Errichtung komplexer Anlagen und bei der Kundenbetreuung. |

|||||||

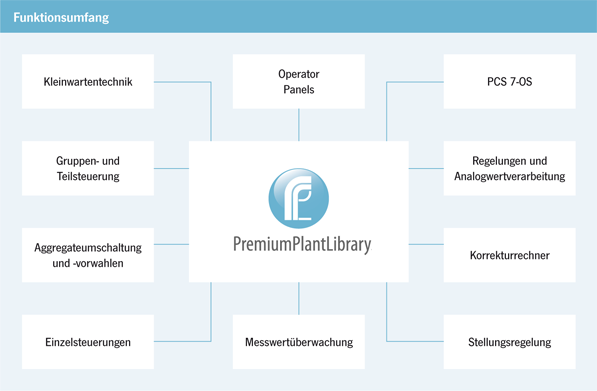

VGB-StandardDie Anforderungen an leittechnische Einrichtungen im Energieerzeugungssektor hinsichtlich Bedienphilosophie, Verfügbarkeit und Systemaufteilung sind durch die VGB-Richtlinien R170 B0-B6 beschrieben und definiert.Die derzeit am Markt verfügbaren PCS7-Bibliotheken erfüllen diese VGB-Vorgaben entweder nur unvollständig, sind nicht auf dem aktuellen Stand der Technik oder werden in den neuen PCS7 Versionen nicht mehr gepflegt. Aus diesem Grund hat SAR gemeinsam mit E.ON Anlagenservice eine spezielle Kraftwerksbibliothek, die Premium Plant Library (PPL), entwickelt, die die VGB-Vorgaben erfüllt und den vollständigen Funktionsumfang einer modernen Kraftwerksbibliothek abbildet. |

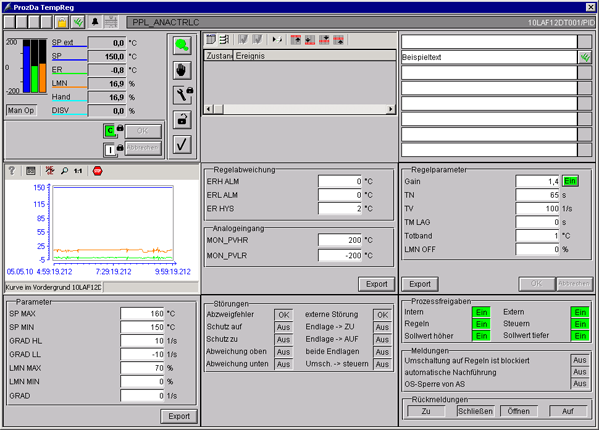

PPL – Premium Plant LibraryEine einheitliche Bedienstruktur, kraftwerkskonforme Darstellungsformen und Funktionalitäten ermöglichen eine effiziente Betriebsführung mit der PPL. Für die schnelle Fehlersuche werden die PCS7-internen Diagnosefunktionen vollumfänglich unterstützt. Freigabe-, Schutz- und Verriegelungslogiken werden visualisiert und übersichtlich dargestellt. Durch die strikte Einhaltung der Vorgaben für die Entwicklung von PCS7-Bibliotheken ist eine Migration zu neuen Versionen uneingeschränkt möglich. Neue Systemfunktionen können jederzeit integriert werden.Spezielle Bausteine ermöglichen die individuelle Anbindung von unterschiedlichen Sensoren, Aktoren und Schaltanlagen. Unterstützt werden z. B. Regelantriebe mit Busanschaltung oder Schaltanlagen mit intelligenten Motorsteuerbausteinen. |

Die übersichtliche Darstellung der Informationen und Eingabewerte in den Kreisbildern ermöglicht es, einen Großteil der Wartungs- und Optimierungsarbeiten ohne Zuhilfenahme der Engineeringumgebung durchzuführen. Systemstatus, Weiterschalt- und Verriegelungsbedingungen werden visualisiert. |

||||||

|

Weitere Informationen über die SAR Group finden Sie unter www.sar.biz

Zum Thema Feuerungstechnologie (Feuerleistungsregelung, Sensorik & Aktorik, Prozessleittechnik, BDE etc.) finden Sie ausführliche Informationen unter www.feuerungstechnologie.com Für weitergehende Fragen können Sie uns jederzeit unter put@sar.biz kontaktieren. |

||||||||

SAR, Elektronic, Prozesstechnik, Umwelttechnik, PPL, Premium Plant Library, PCS7, Bibliothek, Kraftwerk, Feuerleistungsregelung, VGB, VGB-konform, Prozessleitsystem, Industriekraftwerk, Energietechnik

SAR Elektronic GmbH, Gobener Weg 31, D-84130 Dingolfing - Telefon: +49 8731-704-0 - Geschäftsführer: Konrad Sigl - HRB 2022 Landshut - UStId.: DE128961183 - Datenschutzerkärung